Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

NEWS

NEWS

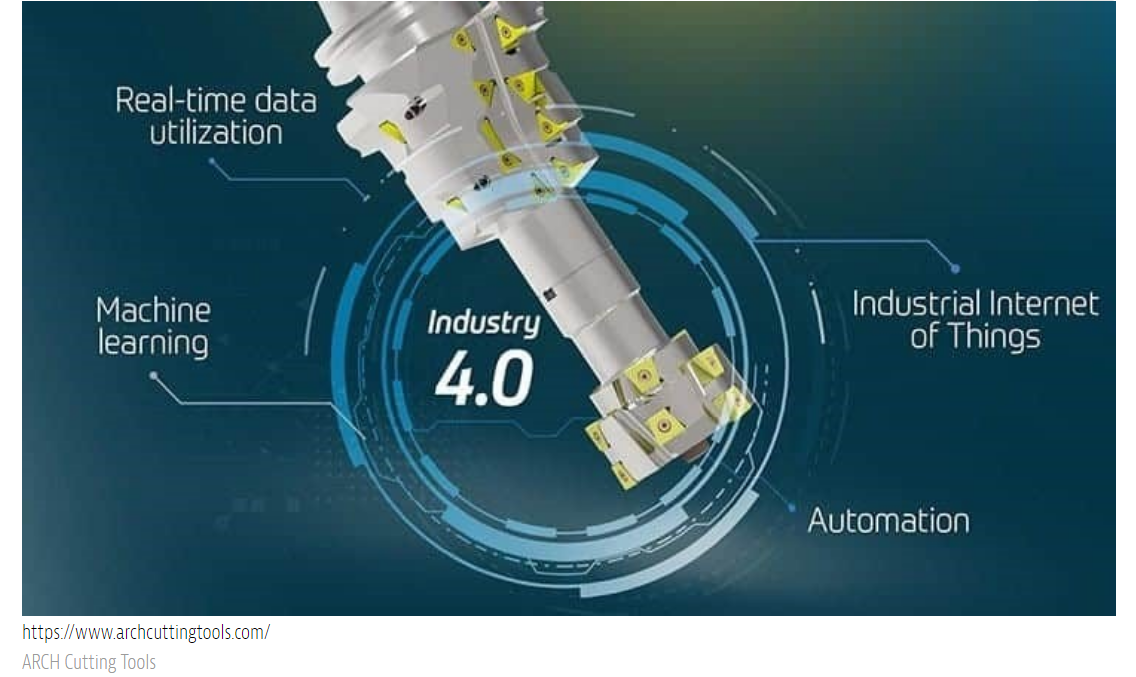

Industry 4.0 and the Industrial Internet of Things (IIoT) are driving today’s manufacturing, combining physical production and operations with smart digital technology. With a heavy focus on interconnectivity, automation, machine learning, real-time data utilization, and artificial intelligence (AI), Industry 4.0 brings to mind high-tech industries like medical devices, aerospace, and computer technologies. Certainly not cutting tools, right? Wrong.

“In the 21st century manufacturing environment, companies are embracing Industry 4.0 technologies, and efficient access to digital product data is essential to meeting the level of precision that is required in the cutting tool industry today as well,” says Bill Orris, ARCH Cutting Tools senior director – Product Development and Custom Solutions. “We are now capable of exporting tooling data of our products directly to our customers’ CAD/CAM, ERP, and other shop environment digital platforms, fast-tracking solid modeling and simulations.”

A giant leap for a 20th century business you may think. But some historical perspective will demonstrate that this is really an evolution.

First, what is Industry 4.0? It’s the fourth industrial evolution that began around 2000, with data becoming a primary driver of manufacturing. The history of industry and manufacturing is summarized in the previous three industrial revolutions – around 1765, when the production of goods became mechanized, followed by the second industrial revolution in 1870, when industry became electrified, and the third industrial revolution in 1969 when electronic automation was introduced.

So, it’s time for the cutting tools industry to catch up, right? It’s not a matter of catching up, but rather evolving and innovating along with the rest of manufacturing. Cutting tools and material removal technology have been a critical part of each industrial revolution.

When the production of goods first became mechanized, there could have been no standardized, repeatable, reliable parts production without standardized, repeatable and reliable cutting and drilling.

As industry evolved, cutting and material removal technology had to be at the forefront to support faster, more efficient production; and to handle new and more diverse materials as they entered the markets.

Now, as data and digitization drive manufacturing, cutting tool technology is again leading the way – as it did in the late 1700s at the dawn of the first Industrial Revolution.

Cutting tools have always been “high-tech,” as defined in each era; and now, just as with all industry, the high-tech component is digital, and data driven. That’s how the cutting tools industry continues to lead in manufacturing, and ARCH Cutting Tools is setting the industry standard with its approach to digitization, cloud-based management of customer data and information, and the integration of its solutions.

Tools Communicating with Software

Industry 4.0 is touching the cutting tools industry from quote to delivery, according to Orris.

“Tools are becoming ‘intellectual’ because that’s what’s needed in today’s industry,” he says. “Through sophisticated technology and embedded chips, tools are communicating with software to collect data that’s critical to achieving efficient manufacturing. Understanding the data and applying what’s learned is the key to efficiency.”

The cutting tools industry traditionally relied on tribal knowledge – learnings through experience applied expertly to address new challenges and drive innovation he explained. But that is changing.

“We’ve stopped looking back and are applying Industry 4.0 principals to become predictive,” he says. “Data collection and management allows the industry to apply predictive analytics. At ARCH, for example, we built out comprehensive data platforms that allow us to predict performance and enhance the return on investment for our customers by optimizing performance and avoiding unanticipated failures.”

Does that mean smart tools don’t require a human component?

“The human intellect, our experience and insight, the innovative nature of experienced professionals will always be critical to effective AI,” Orris points out. “Technology – including cutting tool technology – can’t exist and evolve without human blood, sweat and tears!”

It’s in understanding how to use the data, and sometimes finding unforeseen uses for the data, that takes the insight and expertise of professionals, he added.

“Data becomes stronger and more complete day after day, as it is collected,” Orris says. “But in our industry, it’s still all about the experience that applies what we’ve learned from the data. Experience and the principles of Industry 4.0 are complimentary. The tools of Industry 4.0 allow us to use our experience more effectively.”

The digital cutting tools industry futureThe goals of manufacturing in the future are essentially the same as they were at the dawn of the first industrial revolution – reduce cycle time, reduce errors, boost productivity, improve quality, increase profitability.

“Industry 4.0 principals have helped us reduce our own learning curve,” Orris notes. “The speed of change in today’s manufacturing demands an unprecedented nimbleness and rapid innovation. We need to position ourselves to apply our understanding of data so that we’re ready for anything.

“Anything” can mean new materials, or a new variation of an existing material, new processes in manufacturing, or simply unforeseen demands or impacts on the manufacturing industry.

“We’re successful,” Orris explains, “when we can effectively apply data to respond to a manufacturing challenge, rather than react to it. It’s a subtle difference, but responding leads to a direct solution, while reacting often wastes time in first trying to figure out a solution. At ARCH, we want to be the first responders of the cutting tool industry.”

ARCH Cutting Tools had made a significant investment in its digital processes, Orris notes. This is important to creating customer value. With ARCH Specials, for example, applying a refined digital design based on customer data up-front in the production process, the need for design variations can be reduced by 50%.

“With Industry 4.0, we are creating tools that are highly connected to their applications,” Orris added. “In the field, tools are mis-applied at a rate as high as 70%. Using our digital process, we focus on reducing that 70% to – ideally, 0. We’re always looking for ways to control variables and maximize efficiency.”

Bill Orris, ARCH Cutting Tools Senior Director – Product Development and Custom Solutions, is an Industry 4.0 expert and a cutting tools industry innovation leader.

The four Industrial Revolutions – historical overview

Industry 4.0 is not a buzzword. It is a description of our current fourth industrial revolution – a historical evolution; following the previous three. Here are the four generally recognized industrial revolutions (all dates are circa):

1765 – production of goods becomes mechanized, and the world economy shifts from agricultural to industrial. Coal is the primary fuel, steam the primary power. Metal forging and cutting is standardized.

1870 – industry becomes faster and more efficient with the discovery/harnessing of electricity. The new fuels are gas and oil – powering more powerful, more efficient internal combustion engines. Metal forming becomes more sophisticated with these advanced techniques. Steel and newly developed chemical-based materials begin to take over the market.

1969 – industry enters the nuclear age (primary power in Europe, less so in the U.S.) and is dominated my electronic automation. Materials are becoming more diverse to meet new, expanding markets (aerospace, electronics, etc.) and materials handling in manufacturing becomes more complex.

2000 – for the first time, the primary changes to industry and to manufacturing are not driven by power, fuel, or materials; but are driven by information – data is the new driver. In the fourth industrial revolution, digitization has created a real-time connection between every process and component of manufacturing – design/engineering, the production line, delivery, even end-of-life disposal. The Industrial Internet of Things, cloud technology, AI – all these are merging the physical and virtual manufacturing worlds.