Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGY

Martine Jagger describes how operators maximise efficiency and reduce maintenance costs

According to the Global Wind Council, 2020 was the best year so far for wind energy production with 93 gigawatts of new capacity installed. That’s a 53% year-on-year increase! However, as the wind energy industry grows, the demands on turbines grows too as older turbines outlive their original lifespan and the size of modern turbines increases. From being able to produce just .5MW 20 years ago, design improvements mean today’s turbines can deliver more than 13MW, but this places more torque and pressure on generators leading to grease deposit build up in the generator and the risk of overheating and shut-downs.

Unplanned maintenance leading to the loss of power generation is an expensive cost to your business, but replacing a wind turbine generator can take weeks, which is why optimised maintenance and extended service life is integral to wind farm operation.

Klüber Lubrication has a long history of supporting the wind industry to maximise efficiencies and returns on investment with a range of biodegradable lubricants specifically developed for wind turbines to keep maintenance costs down and achieve sustainability goals. The company offers several solutions to improve efficiency and reduce maintenance costs.

Clean components lead to production increases

Over time, grease deposits build-up in the generator bearings, mainly because of hardened thickener due to oil separation at higher temperatures. This can lead to vibrations, bearing damage and even turbine shutdowns caused by temperature spikes, which means additional maintenance hours, spare bearing costs and a loss of energy production.

Conventional flushing oil will not fully remove these deposits, but by using a flushing grease containing special cleaning particles, such as our newly developed cleaning grease, deposits can be removed even while the turbine is still in operation.

Klüber Lubrication’s new cleaning grease is compatible with other base oils for maximum versatility and is proven to reduce temperature shutdowns to almost zero. As well as removing residue from rolling bearings, it also offers good protection against wear and corrosion.

Grease is the word

Issues with generator bearings are one of the most common causes of unplanned maintenance work at a wind farm, sometimes taking 24 working hours to replace the bearings. Up to 90% of this can be avoided by cleaning the bearing with a special grease, then switching to a newly developed generator grease, which will protect the generator bearing in future.

Klüber Lubrication’s recently developed generator bearing grease combines synthetic base oil and a new generation of calcium complex thickener, which delivers superior performance compared to current technologies in all standard tribology tests.

The higher performance capabilities of this product mean less lubricant is required, maintenance costs are reduced, operational hours are extended and profits from your turbines are maximised.

Bearing the brunt of preventative maintenance

Up to 70% of operational costs are due to unplanned maintenance, with the main gearbox, the main bearing, the pitch bearing and the generator bearing being the biggest sources of downtime. Under-performing oils impact efficiency and energy output and can lead to critical components not reaching their projected operational lifetime, which is why it is important to know the condition of your oil and grease, and to draw the right conclusions from your oil and grease condition report to maximise component life: changing the lubricant too early is as bad as being too late.

An analysis report can reveal a lot about the wind turbine and the condition of components. For example, water contamination of the gear oil or bearing grease can be caused by a sealing malfunction, whereas the presence of phosphorus and sulphur indicate low additive levels and the need for a lubricant change.

Klüber Lubrication has vast oil and grease analysis experience and in cooperation with leading bearing manufacturers and wind farm operators, the firm provides tailor-made analytics and recommendations to ensure the optimisation of grease life and bearing operation hours in wind turbines.

Products for our planet

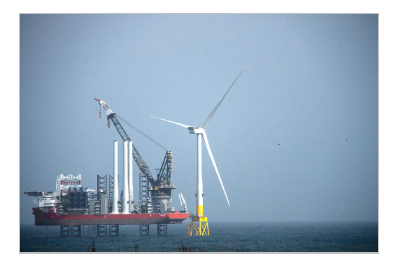

Increasing environmental concerns, social influence, corporate governance and tighter regulations are encouraging wind farm operators to choose more sustainable products. For operators of offshore wind farms this is especially relevant as the open yaw drives and yaw slide bearings can be affected by harsh weather and salt water, which demands products with outstanding lubrication properties, suitable for all conditions and temperatures, to resist wear and corrosion. Klüber Lubrication has delivered high-performance lubricants with a low environmental impact to meet a range of industrial challenges. In the wind industry its new biodegradable grease allows for the smooth operation of both the yaw open gears in all temperatures and weather conditions whilst also protecting the environment.

One turbine: one grease

Having one grease that can be used in a variety of wind turbine applications across a range of temperatures has clear benefits. It reduces complexity by streamlining logistics, minimises the potential for cross contamination with other greases and delivers consistent component protection. The company’s multi-application grease is designed for maximum performance in generator bearings, blade bearings, main bearings and the yaw bearing when equipped with roller bearings. It can help to achieve low rotational resistance, maximum protection against false brinelling and long-term wear protection. In addition, it delivers sufficient oil separation, low flow pressure even at low temperatures, efficient reflow behaviour and good corrosion resistance.