Welcome to Sino Bearings web

24x7 HOTLINE:+86-28-81454188

TECHNOLOGY

TECHNOLOGY

When it comes to proper bearing lubrication, what is your confidence level?

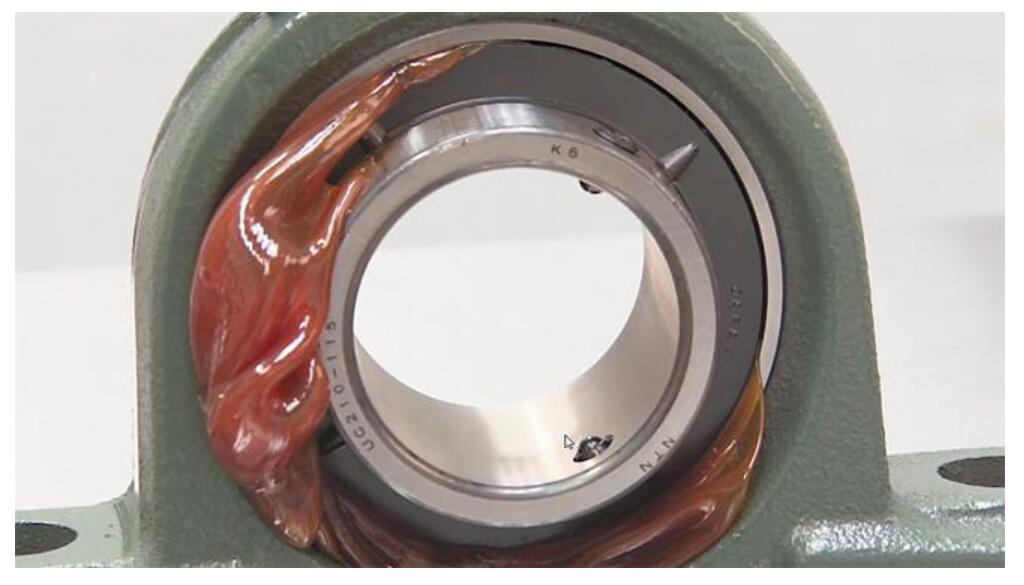

Determining both the frequency and quantity of lubrication are two perplexing issues facing technicians responsible for maintaining bearings. What happens if you use too much (or too little) grease on bearings?

Underlubrication can cause a bearing to wear out before its time, while applying too much lubrication often leads to catastrophic results for the bearing. It can even cause long-term damage to motor coils and windings.

With the help of ultrasonic tools and a little lubrication knowledge, technicians can make better greasing decisions or even automate the monitoring and greasing process.

The Current Mindset

Traditionally, lubrication scheduling has been time-based with equipment suppliers often recommending lubrication schedules set on criteria such as hours of operation. Suppliers frequently also provide instructions on the amount of lubricant to be applied during these scheduled maintenance procedures. It is not uncommon for clients to be told to lubricate at short-term intervals and to add what appears to be excessive amounts of grease. In one instance, a client was advised to lubricate motor bearings every two to three weeks and to add one ounce of grease. The origin of these suggestions leads one to speculate that they are often based on some unknown factors that have no real-world application.

A system of training, tools and planning that allows your staff to really “listen” to your bearings and understand exactly how to properly lubricate them could be invaluable in preventing early failures, unexpected production interruptions and other costs and issues related to under or overlubricated bearings.

Lubrication Intervals & Equipment Optimization

Lubrication intervals are based on a simple premise: keep equipment running optimally by preventing a bearing from running dry and causing catastrophic damage. While it is a solid preventive concept, a balance must be struck between preventing lubrication starvation and gross overlubrication.

To achieve equipment optimization, you need to know when to lubricate and when to stop applying lubricants to a bearing. How do you do this? By utilizing a condition-based lubrication strategy and letting the condition of the bearing determine when to lubricate. If a bearing is working properly and does not demonstrate any changes that warrant adding lubrication, the bearing should be left alone.

Should conditions change and a bearing demonstrate a need for lubrication, then a lubricant should be applied. Monitoring the bearing as the lubricant is applied will also help determine how much to add and when to stop the application.

Understanding Ultrasound Technology

Ultrasound technology is ideally suited for condition-based lubrication methods. To understand why, one must understand the ultrasound technology, how ultrasound is produced by bearings and how ultrasound-monitoring instruments can help maintain optimal lubrication levels in bearings.

Ultrasound technology is based on the sensing of high-frequency sounds. Ultrasound starts at 20,000 cycles per second, or 20 kilohertz (kHz). This is considered the high-frequency threshold at which human hearing stops. Most ultrasonic instruments will sense from 20 kHz up to 100 kHz. The range of human hearing covers frequencies from 20 cycles per second (20 Hz) up to 20 kHz. The average human will often hear up to 16.5 kHz and no more.

Ultrasound Instrumentation

Instruments based on the technology of airborne/structure-borne ultrasound are referred to as ultrasonic translators. These translators receive the inaudible high-frequency sounds and electronically translate them into the audible range through a process called heterodyning, which works in a similar fashion to an AM radio.

While we cannot hear radio waves, this method helps us easily identify different voices and musical instruments when we listen to the radio. Similarly, this heterodyning process provides an accurate translation of ultrasound produced by operating equipment and enables users to readily identify one sound component from another.

Most ultrasonic translators provide feedback in two ways: through headphones and on a meter where the amplitude of these sounds can be viewed as intensity increments or as decibels (dB).